Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Today we will tell what you need to know about 2D and 3D AOI systems (Automated Optical Inspection Systems).

As technological changes remain constant in the industry, it is important to understand the future capabilities of the AOI system and the flexibility of inspection tools. Will the system always be post-reflow? Are you going to seek to put the system in a new position on the line? What technologies are you building today and what is your future manufacturing road map?

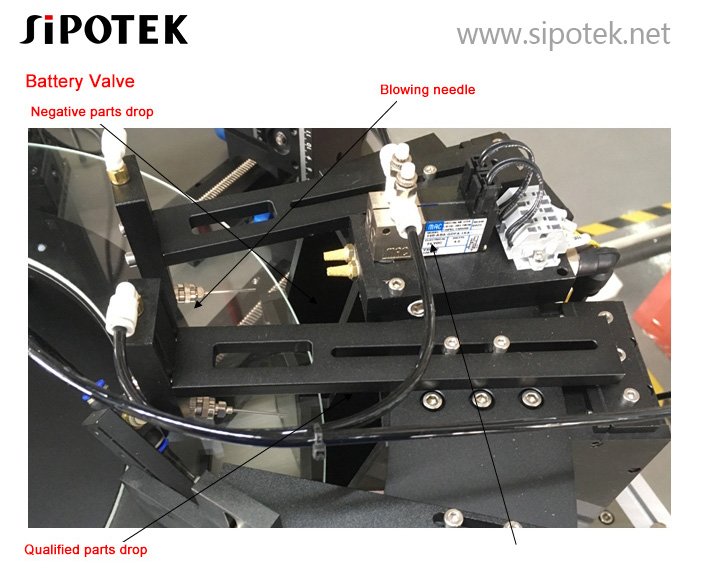

Some AOI systems focus on a single task, i.e. Paste, Pre-reflow, Post-reflow or Post-wave. AOI’s most experienced suppliers will provide solutions covering all aspects of the manufacturing line in the same system, provide integrated 2D / 3D technologies and, at the same time, provide resources for the inspection of semiconductors and microelectronics.

AOI machine price is $120,000 for a good in-line unit and about $60,000 for a good bench-top unit.

The use of AOI is justifiable if you spend a lot of time to visually inspect your tables. The AOI machine is faster and more reliable than human element for the job. In addition, visual inspectors do not add quality to a product and are not generating revenue for the company. If the inspection is necessary (due to defects) and more than one person is dedicated to this operation, then the AOI is obvious. Then, you use only one person to inspect and give others something productive to do.

Correcting manufacturing problems should be based on concrete data. But difficult data is difficult to obtain from human beings. They pretend to see (and repair) what they, and. better understood or what is easy to justify. This effect can be eliminated with an AOI. If it is programmed correctly, you will be informed about the SPC and advise what to do. Most bench systems have their difficulties with the inspection of welding joints. But weld joints provide information about the printing process. This is considered to be a basic and necessary function.

After reflux, the AOI makes sense because it has the highest coverage of the defects. Problems such as raised pins, gravestone, open welding joints, some short and insufficient welding will not find before the oven. I would also not agree with the claim that AOI cannot do anything to prevent defects from occurring. The AOI can notify you in time to prevent the problem from occurring on the large number of plates – for example, warn in case of repeated defects found, so that you can correct the problem before it affects a large number of plates. Incorrect component, for example. You can also identify specific problems of fide or head P & P, if the connection to the P & P line is available. Using the SPC you can easily see your main problems and improve the agreement process. You can evaluate the capacity of your line for a certain process and so on.

Do not make the common mistake of focusing your evaluation on only one aspect of an AOI system. Megapixels alone are not important, programming times in a demonstration can deceive and not lose focus on your real need for AOI.

The coverage of defects, flexibility of the manufacturing strategy, use of measurement data, productivity, stability of the company, reliability of the system, programming and support times of ongoing programs, all need to be judged equally, in addition to the acquisition cost of a system.

The defects cover must always be the first reason to use any inspection platform. If you understand your manufacturing process and focus on the defects generated in your process, the AOI system will always provide maximum value and ROI, while increasing its overall quality.

To learn how a aoi system can automate the production process, one can visit the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Website: https://www.sipotek.net/