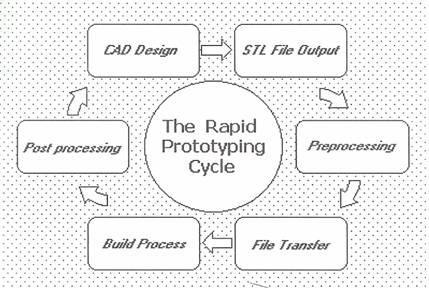

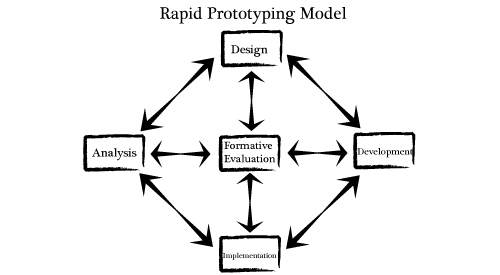

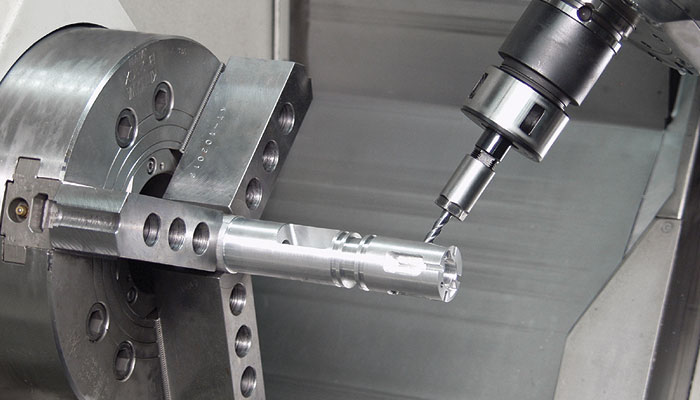

JasonMould Industrial Company Limited is a professional china plastic injection molding company for 3D Printing Rapid Prototyping Service,precision CNC milling service and custom CNC machining services,custom plastic injection molding or moulding company with mould and dies development and manufacturing.

Today we will discuss die casting vs injection molding- which is better: plastic injection molding or die casting process?

What is Injection Molding?

It is considered to be one of the most popular manufacturing processes today. It is widely used by custom belt buckle manufacturers. Depending on what is needed, raw materials can be made of metal, glass, confections, or elastomers. But the most popular raw material is plastic.

How Are Products Made with Injection Molding?

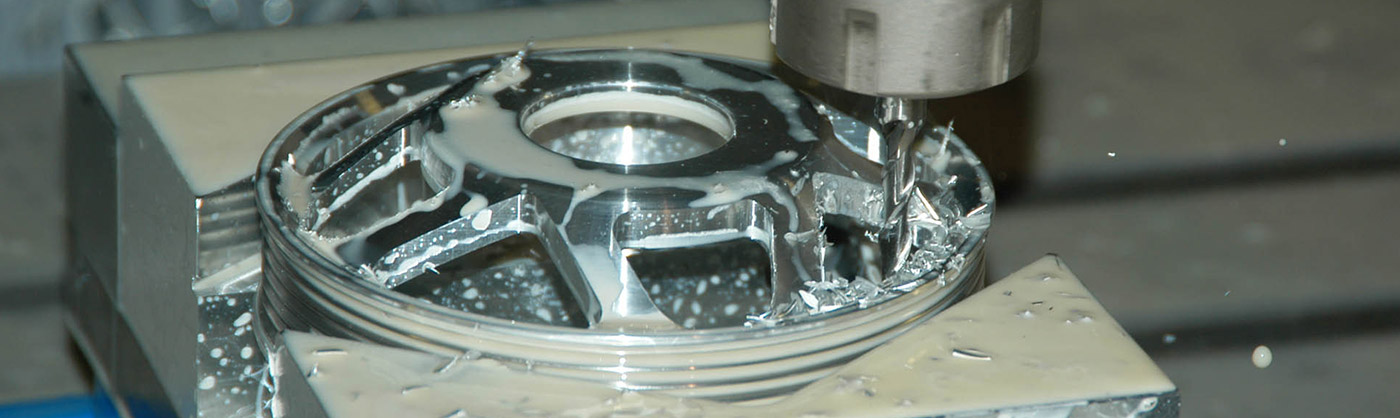

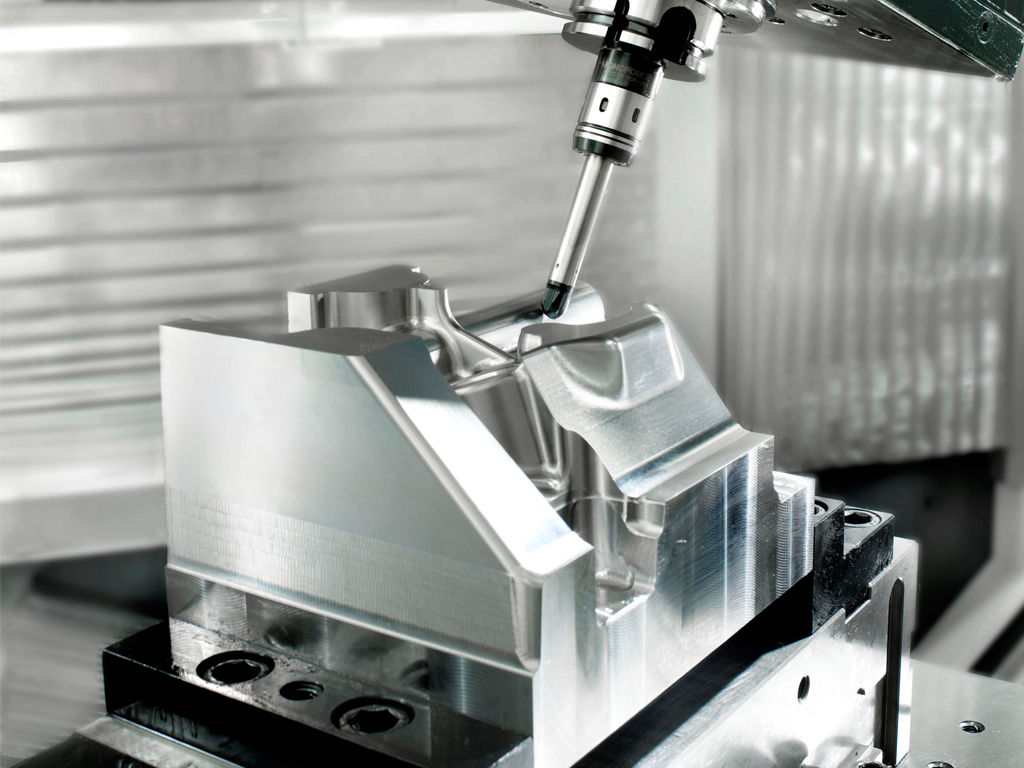

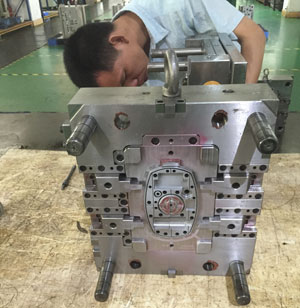

First, design and plans must be finalized. After everything is ready, raw material like duraflex material will be melted in a big barrel. After melting, it is injected into a mold that is usually made of strong metal. After taking the shape of the mold, it is allowed to cool and ejected from the machine. These are the injection moulding process parameters.

Some products manufactured under this method are automotive parts, toys, kitchen utensils, combs, bottles, appliances, educational supplies, strap buckles, and a whole lot more.

The Injection Moulding Advantages

This manufacturing process has a lot of advantages. First, it is very cost effective because little or no waste is produced. Second, it is very eco-friendly due to the first reason. And third, it produces high quality products. With all of this in mind, can you even imagine a life without injection molded plastic?

What is Die Casting?

Now that you are already familiar with injection molding, it will be easy for you to understand what die casting is. Unlike injection molding, die casting only engineers various metal parts or products made of metal.

How Are Products Made with Die Casting?

The process is also similar to injection molding. Raw materials made of metal is melted under extreme but exact temperature, forced into durable steel molds and allowed to cool before taken off the machines.

Are you a toy car collector? Your toys probably are made through the die cast system. Steel pipes, car parts, electronics, golf equipment, and faucets are just some of the products made through it as well.

The Die Casting Advantages

It has numerous advantages. First, the system can be done in an automatic fashion. Second, the molds can be used over and over again due to its durability. Third, the products made through this are more durable and has a longer service life. And fourth, it is economical too!

Mold making and casting is a fascinating activity which can take varied forms. From clay modeling to making simple one-part molds or the more complicated approach of two-part molds. In fact, mold makers even make multi-part molds at times to capture all facets and other details of the model. The procedure of making molds also varies from pouring the mold making material to spraying it or even brushing it on the model.

Apart from the regular blanket, glove and even shell type, another making and casting technique is injection molding. It is actually a simple procedure in which the casting material is forced into this under pressure!

Injection molding can be done in single or multi-part molds. Since it is favored for capturing minute details, generally complicated two-part molds feature in injection molding. Tiny holes (called sprues) are bored into the mold all along its surface. This is where the casting material will be injected into this.

The casting material like polyurethane resin is filled in a syringe and the large hypodermic needle is inserted into the mold sprues. Pressure is applied to ensure all cavities are filled. The procedure continues until the casting material spews out of all the sprues. This shows that the casting material has displaced the air inside the mold and adequately filled all the nooks and crannies in the mold.

It is allowed to cure before being demolded carefully. You will find a thin-bodied cast that is an exact replica of the original model, down to every tiny nook and crevice. Other casting methods fail to achieve such a high level of precision. The demolded piece does not need to be cleaned or finished much either. However, models with large undercuts cannot be replicated with injection molding.

Injection molding is a commonly-used manufacturing process for producing thin-walled parts with great accuracy. It is generally used to make small plastic, metal and even glass items. Model parts for miniature cars, trains and complicated superhero figures are made with the injection molding process. It will yield accurate copies very quickly and in large numbers too.

The manufacturing process involves feeding the casting material into a machine which crushed it to a liquid state before injecting the same into the mold under high pressure. This mechanical process is repeated again and again to make multiple copies. The plastic in the mold is allowed to cool before being ejected from the mold.

While injection molding is a simple process that proves cost-effective, making the molds can turn out very expensive. It has to be made with steel or aluminum and precision machined to capture all the details properly. However, when artists use injection molding technique in their studios, they make use of clay modeling techniques and silicone rubber to make a precise block mold. This serves well for injection molding!

If you are looking for a die casting or a plastic injection molding company,jasonmould will be your best choice to be consider!

About JasonMould Industrial Company Limited

Jasonmould is a manufacturer of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer- plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

Contact:Person: James Yuan

Company: JasonMould Industrial Company Limited

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Tel: 86-752-6682869

Email: james@jasonmolding.com

Company: JasonMould Industrial Company Limited

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Tel: 86-752-6682869

Email: james@jasonmolding.com